I take apart a lot of little gadgets and I can’t always find ways to get inside them (see dozens of my tear down videos on my Youtube channel). Either the screw heads are stripped, or parts (usually wheels on toy cars) are pressed onto shafts and I can’t get them off, or the thing is glued together and I need a saw of some sort to cut it in half.

I’ve been using a little Dremel tool with a cutting wheel which works great, but doesn’t cover enough distance fast enough, or can’t get deep enough to say, cut off axles that have wheels pressed onto them.

I tried a little reciprocating saw with a fine blade and also a medium blade, but it wasn’t much use.

Reciprocating Saw

So now I’m going to try a different approach — mentioned below. I’ll report back after I’ve used it a little.

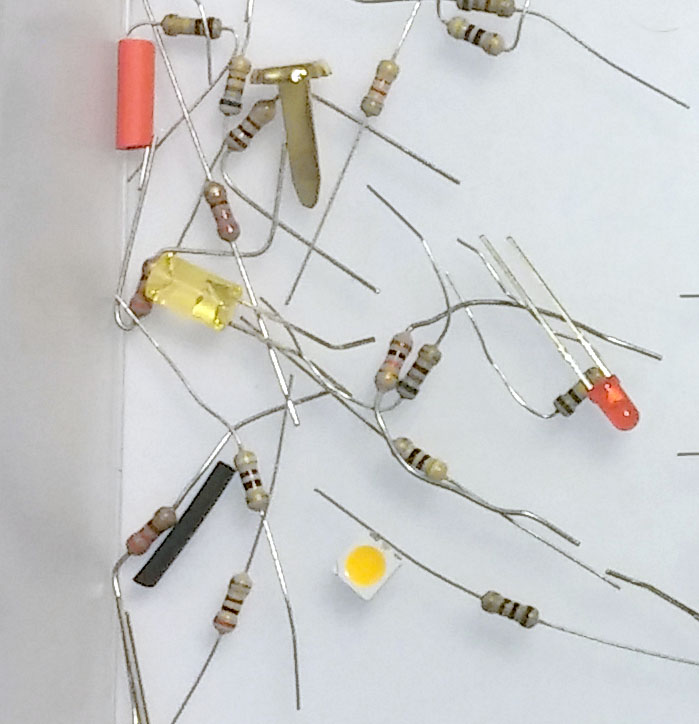

I’m talking about two very similar tools — angle grinder and cut-off tool. I’ve learned some differences, a few that I haven’t seen mentioned anywhere else, so I thought I would share what I’ve learned.

Both tools can be used to grind things, or cut metal. Either grinding wheels or much thinner cutting wheels can be used on either. Accessories like hole saws and wire brushes can be used with an angle grinder — I’m not sure if they can be used on a cut-off tool.

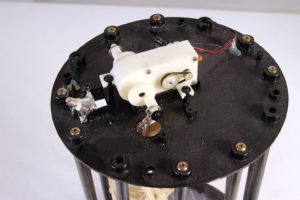

Angle grinder

An average angle grinder typically uses 4-1/2″ discs, has a speed of around 11,000 RPM, and draws about 4 Amps. It has one or two handles that are usually moveable to at least two positions. Inexpensive ones have a screw to adjust the safety guard, more expensive ones have a quick-release lever.

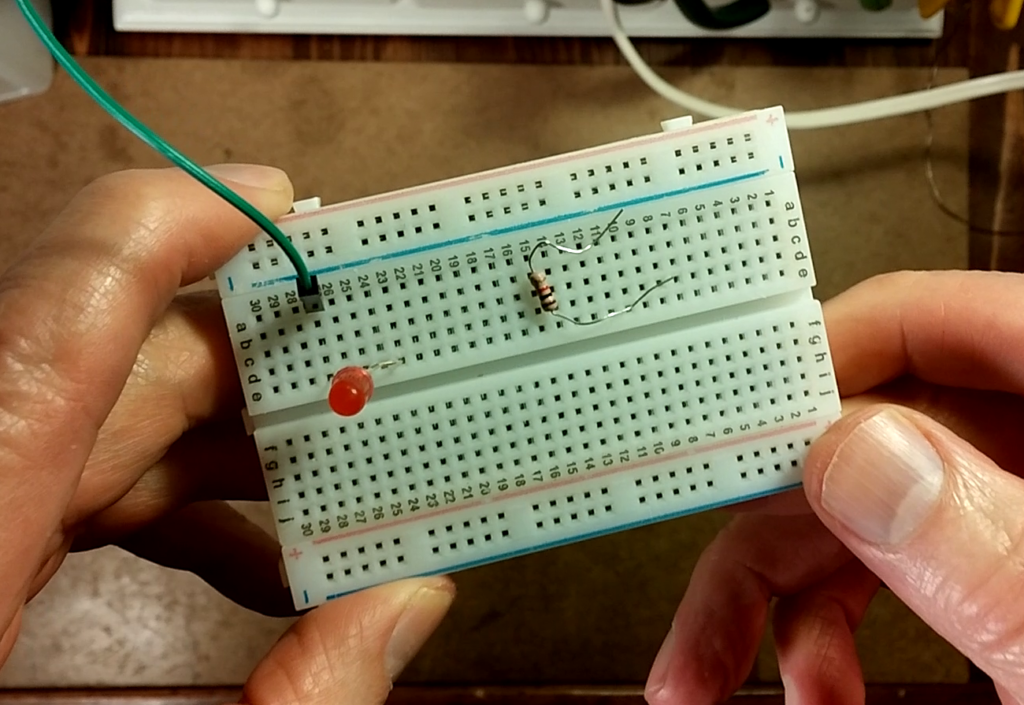

Cut-off Tool

The cut-off tool typically uses 3″ discs and has a speed of around 20,000 RPM, at 3 Amps. It only cuts to a depth of about 1″ and doesn’t have any handles. So it’s smaller, but faster, which I assume is the advantage of using this over an angle grinder for cutting things.

Safety tips

Both tools spew sparks and bits of painful and molten pieces from the wheels and from whatever you’re grinding or cutting. Good safety glasses are imperative.

Face shields are just as good an idea as safety glasses. It will keep sharp or molten chips off of your face, or heaven forbid — a shattered wheel flying into your face!

A dust mask and hearing protection can also be very good ideas.

And don’t forget that protective gloves ara a good idea to help prevent injury to your hands from hot, flying debris, or if the material or tool get away from you. Gloves aren’t going to stop a cutting wheel, but may lessen injury, and will prevent or reduce injury from a grinding wheel.